Plural component coatings are rapidly gaining popularity in the industrial coatings industry. These systems are becoming widely recognized for their ability to provide superior substrate protection for bridges, pipes, marine vessels, as tank coatings and linings, and more. Plural component coatings deliver numerous benefits beyond the faithful protection of an asset. While they’re not right for every project, these coatings systems are capable of providing serious value in certain situations.

What are they?

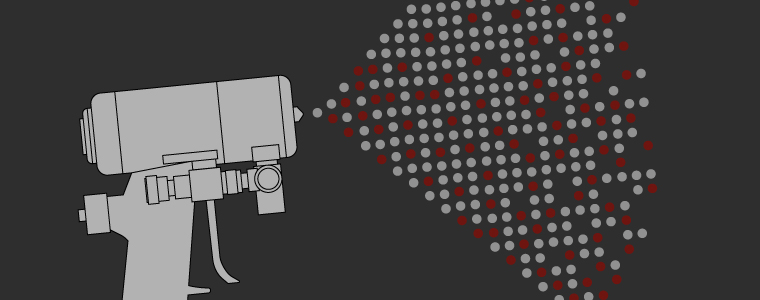

As their name suggests, plural component coatings are made up of separate elements that aren’t mixed until moments before they’re applied. Parts A and B of the coating system are heated separately to reduce their viscosity. Once the desired temperature and viscosity are reached, the components are sent toward a spray gun in the desired proportion, known as the flow rate. Only immediately before reaching the gun, moments before being sprayed, are the components mixed together. Because the components dry so quickly once mixed, applicators have only seconds to get the system from the mixing block onto the substrate.

Service life

Customers are becoming increasingly savvy about ways to save money on their coatings system. More and more they are realizing that spending more on a product up front can actually cut costs by extending service life. This approach can save money normally spent on maintenance costs and extend the length of time needed between recoats. Due to advances in coatings technology, systems that used to last an average of 5 to 10 years are regularly serving between 15 and 20 years. Plural component coatings are a great example of an advancement in coatings technology leading to an extended service life. As always, proper attention needs to be paid to surface preparation and other aspects of the job, but properties like higher film build tend to lead to longer lifespans for these plural component coatings.

Environmental compliance

To comply with tightening environmental regulations, owners and applicators are on a constant search for ways to curb emissions. Because the high solids coatings that make up plural component systems contain relatively few solvents- and none in the case of 100% solids- few if any volatile organic compounds (VOCs) are released into the atmosphere. Plural component coatings are an environmentally friendly option for reducing the emission of VOCs and HAPs. They make it easier to comply with regulations and reduce solvent waste.

Turnaround

Faster cure times mean your asset is back in service quickly. As an added benefit of rapid drying time, plural component systems greatly reduce the turnaround time that accompanies your painting project. If downtime equates to lost revenue for your asset, this may be another way of investing in a product up front that can lead to project savings in the long run. After application, these high solids coatings can be walked on in a matter of hours. Storage tanks no longer take days before they can be put back into service.

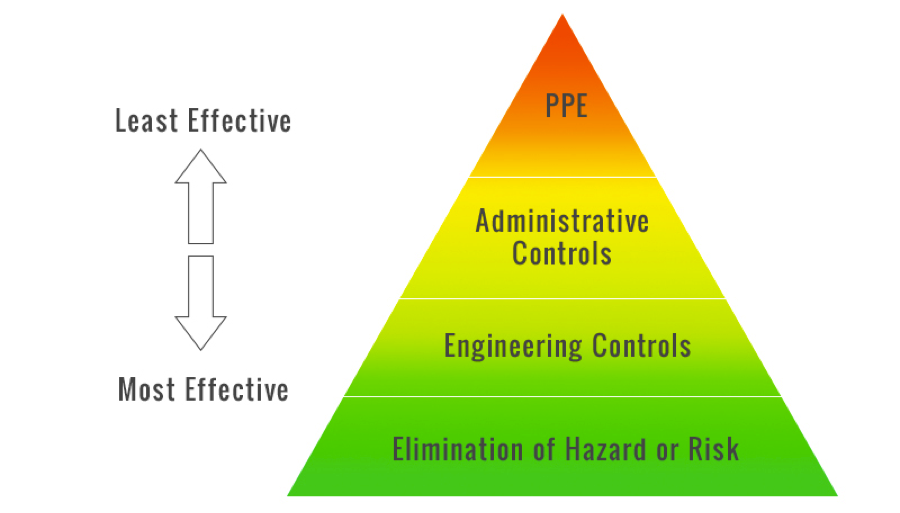

Safety

As applicators ourselves, the added safety benefits plural component coatings offer our crews is a huge draw. Since high solids emit little to no solvents during the application process, the risk of buildup of explosive VOCs is reduced or eliminated. When working in confined spaces like those in storage tanks, this removes one of the most significant dangers to crews.

Let’s talk

Plural component coatings may or may not be the best option for your project. Whether or not they are will depend on a number of circumstances. It’s best to discuss your project with a qualified coatings professional before you decide. And while you’re considering an industrial painter, check out our buyer’s guide through the link below for all the factors to consider before making a hire.