Being a safety leader in our industry is a top priority for us here at Thomas Industrial Coatings, and we know that being leader requires embracing the latest industrial safety technologies, before our competitors do.

A survey on behalf of the Engineering News-Record found that 94 percent of general contractors intend to be using tablet technology on their job-sites by 2015. The numbers are a bit lower for specialty contractors. At Thomas Industrial Coatings, we’re proud to say we’ve deployed them for nearly two years.

TruQC, a cloud-based, quality control app, comes with a host of safety reports that allow our crews to identify potential hazards, record safety meetings and catalog incidents in order to recognize patterns to avoid issues in the future.

Here are a few of the reports and how they help us keep our crews safe on the job-site.

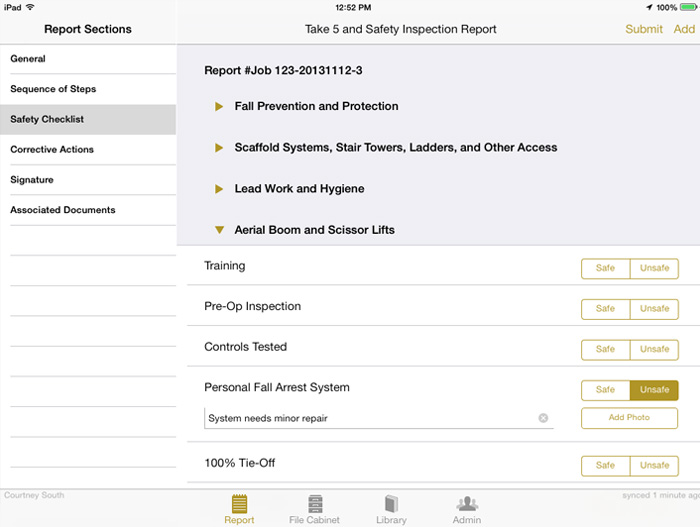

The Take 5 Report

A morning safety briefing, or a “stretch and flex” as it’s often called, is a time-out taken prior to the each shift change, and any time the focus of operations shifts on a job-site. It serves the dual function of allowing crews arriving at work to loosen up in preparation for physical labor, and it gives everyone a chance to discuss potential hazards of the day’s work.

TruQC allows foremen to work through a safety checklist with the crew, ensuring that no potential issues are forgotten, and provides a record that each was addressed.

The Toolbox Talk Report

At Thomas Industrial Coatings, Toolbox Talks provide supervisors with an opportunity for more in-depth discussions of job-site safety concerns. They provide an effective arena for crews to learn about and discuss specific ways to make the job-site a safer place to be.

These safety discussions are documented with TruQC, using date, time and GPS stamps to ensure the objectivity of the report. The end-result is documentation that exceeds OSHA safety requirements.

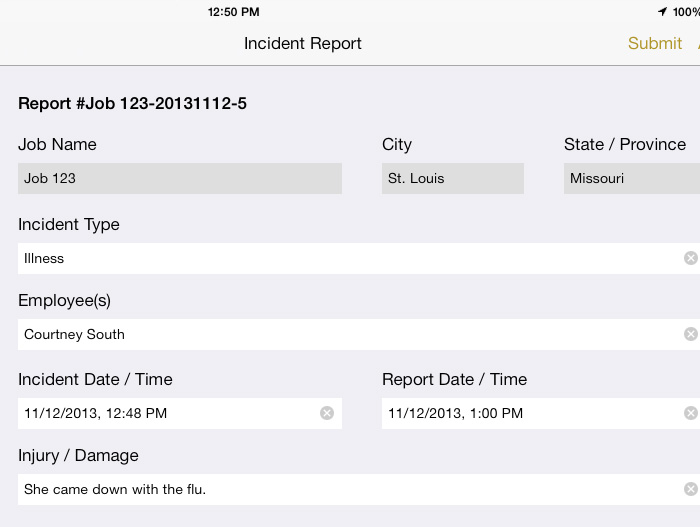

The Incident Report

Here’s where quality assurance comes into play. As data accumulates, trends emerge. TruQC’s Incident Report allows contractors to retrieve safety stats and identify potential risks ahead of time. Serial safety concerns can be identified and addressed before they cause a problem again. Because TruQC is cloud-based, and all our crews are outfitted with tablets, these concerns can quickly be shared with crews in the field.

This is the sort of active injury prevention made possible by data and technology. At Thomas, we’re proud to say we were early adapters. Because making investments in technology for the sake of safety, that’s Thomas Pride.